Micro-screening - a sub-stage in the wastewater disinfection process

Micro-screening - a sub-stage in the wastewater disinfection process

In the course of the project, application rules for micro-screens were drawn up and validated with the aspects of water reuse and disinfection in mind. In particular, this entailed a scientific examination of the mechanical removal of helminth eggs.

Removal of helminth eggs for water reuse purposes

The use of untreated wastewater for irrigation purposes is a standard practice in many places, but it often constitutes a health risk. In particular, worms (helminths) living as parasites are of great relevance to hygiene when it comes to water re-utilization. Against this backdrop, the use of micro-screening to remove helminth eggs mechanically is a highly promising method of reducing health risks.

Extension of the design rules for micro-screening plants

The main goal of the project was to develop and validate a practicable design algorithm for planning, dimensioning and operating micro-screens for wastewater treatment and reutilization purposes, above all for applications in hot climatic zones, where water is consequently warm as a rule. To date there were no standardized design rules for this purpose.

Influencing parameters of relevance to design

Influencing parameters of relevance to design

Solids concentration, helminth egg concentration, turbidity, COD/nitrogen and phosphorus concentrations, water temperature, the screen’s mesh width, the hydraulic load, the duration of filtration, and the backflushing intervals have been identified as relevant parameters having an impact on the design algorithm.

Investigation sites:

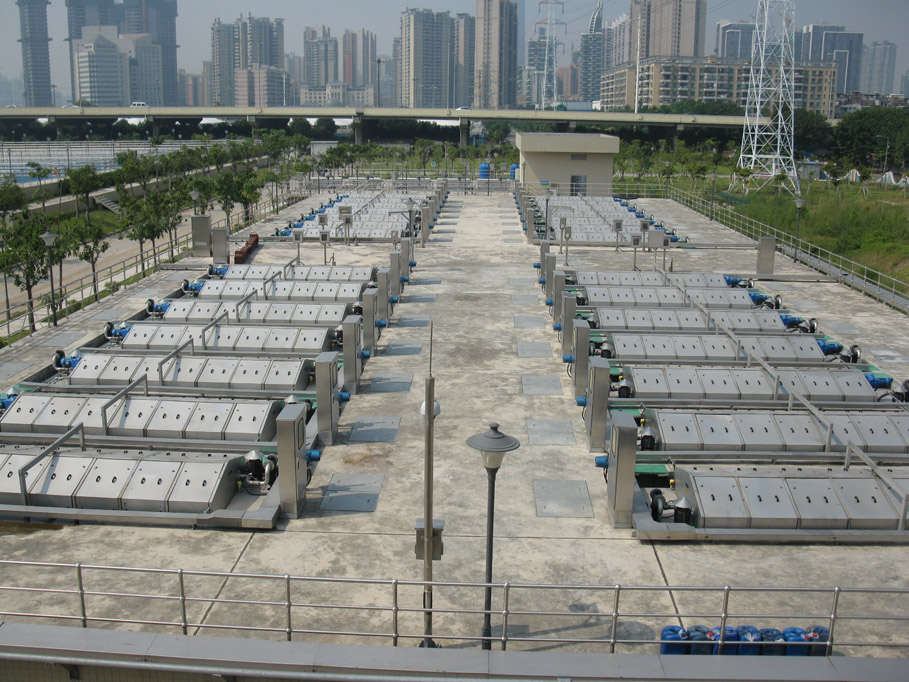

Practical tests have been conducted in Spain and in the UAE, each were carried out on industrial-scale reference plants of the industrial project partner HUBER. Additional tests with containerized pilot systems have been made in Germany and in the UAE.

Operating sequences:

- Obtaining in-depth know-how: A practicable standard process for the quantification of helminth eggs in wastewater was elaborated for the purpose of quantitative analysis of helminth eggs in the course of the project.

- Validation using industrial-scale plants: The performance tests were carried out on micro-screening plants installed on an industrial scale. They covered, inter alia, determination of hydraulic performance at various wastewater concentrations and screen mesh widths, determination of separation performance with particular attention being paid to the retention of helminth eggs, and the wastewater-specific and mesh width-specific fouling of the micro-screens along with cleaning measures adapted to cope with this. A provisional design approach has been formulated on the basis of these investigations.

- Optimization of the micro-screening plants: Using the previous operating step as a point of departure, the micro-screening facilities were perfected in terms of design and process engineering. This had been applied, in particular, to the reduction of fouling potential and the trial of innovative filtration media for the purpose of increasing separation performance and throughput.

- Adaptation of the design approach: The overall results have been evaluated, the design approach was subjected to a final analysis and revised.

Project partners:

Technische Universität Darmstadt,

Institut IWAR, Fachgebiet Abwassertechnik

Petersenstraße 13, 64287 Darmstadt

www.iwar.tu-darmstadt.de

Persons to contact:

Prof. Dr.-Ing. Peter Cornel, p.cornel@iwar.tu-darmstadt.de

M.Sc. Stefan Kneidl, s.kneidl@iwar.tu-darmstadt.de

Huber SE

Industriepark Erasbach A1, 92334 Berching

www.huber.de

Person to contact:

Prof. Dr. Franz Bischof, bf@huber.de